Negative Thick Resists

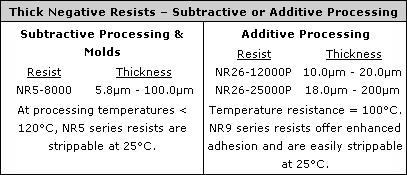

| Thick Negative Resists – Subtractive or Additive Processing |

| Subtractive Processing & Molds |

Resist

NR5-8000

|

Thickness

5.8µm - 100.0µm

|

|

At processing temperatures < 120°C, NR5 series resists are strippable at 25°C.

|

|

| Additive Processing |

Resist

NR26-12000P

NR26-25000P

|

Thickness

10.0µm - 20.0µm

18.0µm - 200µm

|

Temperature resistance = 100°C.

NR26 series resists offer enhanced adhesion and are easily strippable at 25°C.

|

|

- Subtractive & Mold Applications

- Deep etching of silicon, such as Bosch Process, glass and polymers

- Embossing mold for silicone imprints

- Additive Applications

- High aspect ratio plating for the fabrication of bumps for flip-chip packaging, multi-chip modules, MEMS, sensors, thin-film magnetic heads

- Properties for Subtractive & Mold Applications

- Superb temperature resistance in RIE processing and ion milling

- Selectivity superior to that of positive resists in deep etching

- Sensitivity to wavelengths shorter than 380nm

- Properties for Additive Applications

- Superb adhesion during plating

- Easy removal with Futurrex resist strippers after plating

- Sensitivity to wavelengths shorter than 380nm

- Impact on productivity

- Elimination of solvent-based development and solvent-based rinse processing steps

- Features

- superb linewidth control over surface topology

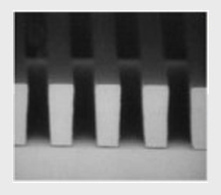

- straight sidewalls for any film thickness

- capability to apply 100 μm thick film in a single spin coating

- superior resolution capability in thick film applications

- superior photospeed enhancing exposure throughput

- facilitates increased power density in RIE/ion milling, which boosts etch rate and etch throughput

- application of a single developer for both negative and positive resists

- elimination of use of adhesion promoters

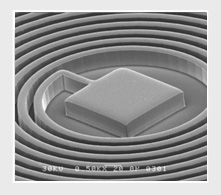

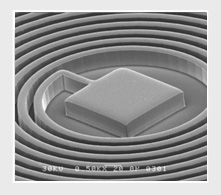

Copper coil plated with NR26-12000P mask after resist removal.

Metal (Cu) Thickness = 25µm

Photoresist = Futurrex NR26-12000P