MEMS

One of Futurrex’s core markets for the past decade has been the MEMS market, which has grown both in the number of products that are created using microfabrication technologies and the number of sockets such device’s can play into. Futurrex has extraordinary products with novel physical characteristics allowing OEMs to create end products that break the mold with respect to differentiation and performance.

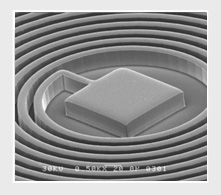

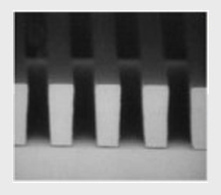

With Futurrex solutions, device designers can quickly prototype their ideas and manufacture devices with extraordinary aspect ratios, in excess of 6:1 at thicknesses of 120 μm or higher, while ensuring quick and full development out of trenches or unique geometries. Lastly all of our products are readily removable or strippable or can be left as permanent parts of any structure.

Such products and associated processing techniques yield uniquely-performing devices at high yield.

We have experience in providing products for a variety of applications spanning semiconductor testing devices to inductive coils and RF-related structures that have evolved from more mature and commoditized technologies.

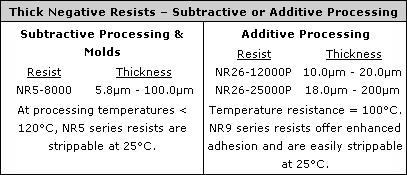

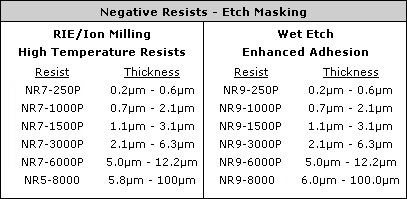

The following is a list of product suites that Futurrex has that can enable a customer to meet their device demands:

- NR9-P-series for trench filling applications and the creation of air bridges over deep trenches thus enabling ideal dielectric conditions

- NR5/NR7-series for deep etching for thicknesses ranging from 10-100+ μm, on a variety of exotic substrates and high energy RIE

- NR26-series for plating, wet etching and advanced adhesion applications with greater than 120μm thickness capability that is readily strippable at aspect ratios greater than 6:1

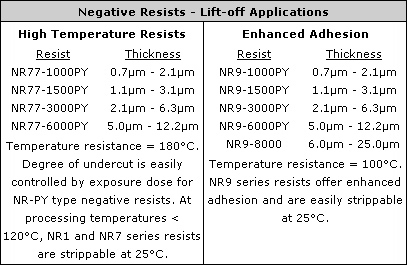

- NR7/NR9-PY-series resists for lift-off applications

- PC4-series for use as temporary adhesive coatings, planarizing coatings and mechanical protective layers

- IC1-series for use in high-temperature lift-off applications, protective and smoothing coating applications