Negative Etch Resists

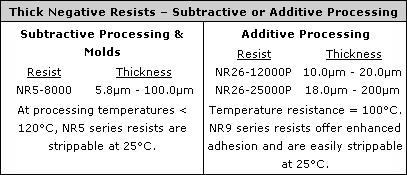

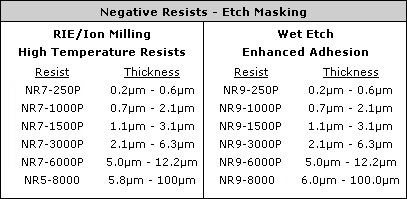

| Negative Resists - Etch Masking |

RIE/Ion Milling

High Temperature Resists |

Resist

NR7-250P

NR7-1000P

NR7-1500P

NR7-3000P

NR7-6000P

NR5-8000

|

Thickness

0.2µm - 0.6µm

0.7µm - 2.1µm

1.1µm - 3.1µm

2.1µm - 6.3µm

5.0µm - 12.2µm

5.8µm - 100µm

|

Temperature resistance = 150°C.

Selectivities of Futurrex NR5 & NR7 resists in RIE outperform commercial positive-tone resists by 25-33% under certain conditions.

At processing temperatures < 120°C, NR5 and NR7 series resists are strippable at 25°C.

|

|

Wet Etch

Enhanced Adhesion |

Resist

NR9-250P

NR9-1000P

NR9-1500P

NR9-3000P

NR9-6000P

NR9-8000

|

Thickness

0.2µm - 0.6µm

0.7µm - 2.1µm

1.1µm - 3.1µm

2.1µm - 6.3µm

5.0µm - 12.2µm

6.0µm - 100.0µm

|

Temperature resistance = 100°C.

NR9 series resists offer enhanced adhesion and are easily strippable at 25°C.

|

|

- Applications

- Replacement for positive resists in RIE processing and wet etching

- Properties

- Thickness range: <0.1 - 120.0 µm

- Sensitivity to wavelengths shorter than 380nm

- Features

- superior linewidth control over surface topology

- straight sidewalls for any film thickness

- capability to apply 100 µm thick film in a single spin coating

- shorter bake time due to application of 150°C softbake (critical for thick films)

- superior photospeed, which enhances exposure throughput

- facilitates increased power density in RIE boosting etch rate and etch throughput

- elimination of use of adhesion promoters

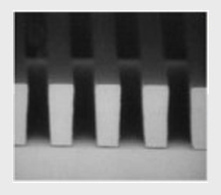

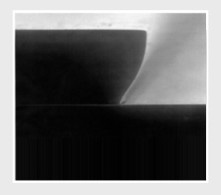

Futurrex NR5-8000, 4.5:1 AR

Example of resist resolution

Film thickness: 54µm

Mask dimension: 12µm line/space

Exposure dose: 1100 mJ/cm2.

Focus offset: -15µm.

Exposure tool: Ultratech Stepper Saturn

Model, i-line