Solar PV

Futurrex offers unique, cost-curve shifting solutions for companies developing solar-related technologies. Our novel products take existing, long-standing processes centered around wet chemistry processing, and apply these techniques to enhancing solar products, shifting cost- curves by orders of magnitude, while increasing throughput and efficiency goals across a spectrum of solar technologies.

For crystalline and amorphous silicon technologies, Futurrex provides spin-on dopants that replace traditional, capital-equipment intensive ion implant applications with low-cost, traditional wet-chemistry processing.

We provide both P and B-based dopant solutions that allow customers quick product development cycles at minute capital cost vs. current technologies, enabling them to reach cost per watt and grid parity goals more quickly.

Such products include:

- BDC1 coatings for Boron doping

- PDC5 coatings for Phosphorus doping

Futurrex has been supplying III/V solar customers including private companies and government entities for the past decade. For III/V PV applications, we offer the following suite of products:

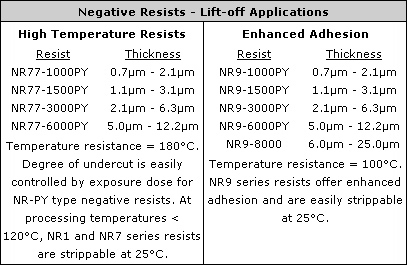

- NR7/NR9-PY-series resists for lift-off applications

- NR9-P series resists for general patterning applications where advanced adhesion is required

For newer thin-film technologies (CdTe, CIGS) that utilize lithography steps, Futurrex offers the following products that can be used in conjunction with physical vapor deposition or roll-to-roll deposition technologies:

- NR7/9-PY-series resists for lift-off applications